Halbeegyada aasaasiga ah

| Qodobbada ugu muhiimsan ee farsamada | ||

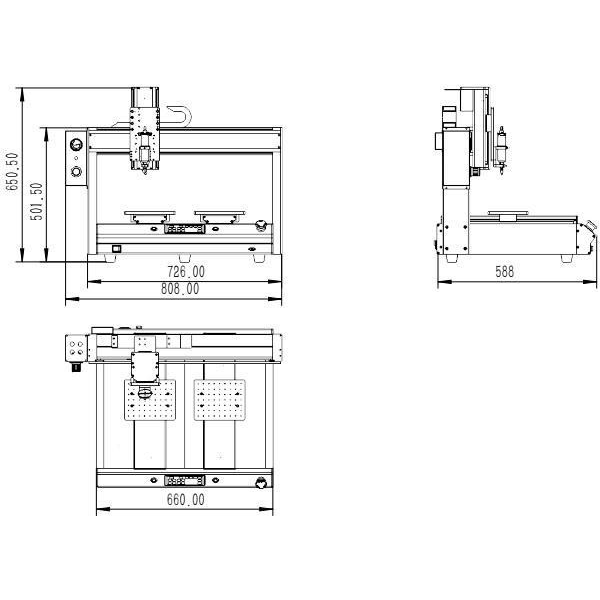

| Qiyaasta dhaqdhaqaaqa | dhidibka X | Qiyaasta la isticmaali karo 500mm |

| dhidibka Y1 | Baaxadda la isticmaali karo waa 300mm (waa la beddeli karaa) | |

| dhidibka Y2 | Baaxadda la isticmaali karo waa 300mm (waa la beddeli karaa) | |

| dhidibka Z | Qiyaasta la isticmaali karo 100mm | |

| Cabbirka mashiinka | L | 808mm |

| W | 588mm | |

| h | 750mm | |

| Miisaanka mashiinka | ≈65KG | |

| Xawaaraha ugu badan | 500mm/S | |

| Aagga qaybinta | (500)*(300)mm waa la beddeli karaa | |

| Ku celcelinta | (Suunka) ± 0.05mm; | |

| Culayska ugu badan | 5KG | |

| Korontada | AC220V/50Hz | |

| Awoodda guud | ≈0.35KW | |

| Cadaadiska shaqada | 0.5-0.6Mpa | |

| Deegaanka shaqada | Heerkulka: 0-40° Humidity: 20-91% | |

| Qalabka quudinta | haanta cadaadiska | |

| Dhumucda shaqaynaysa | 100mm | |

| Nidaamka Xakamaynta | Nidaamka xakamaynta is-horumaray ee Chengyuan | |

| Habka wadista | Mootada Stepper + (suunka) | |

| Xusuusta barnaamijka | 99 qaybood oo xogta habaynta ah waa la kaydin karaa, iyo hal fayl oo farsamayntu waxa uu qabsan karaa ugu badnaan 3M meel kaydinta (5,000 dhibcood processing) | |

Liiska Bixinta Mashiinka Dahaarka Tooska ah ee Desktop

| Magaca | Tilmaamid | Tirada | Unug |

| Ytype tee wadajir | 8-8 | 2 | Shakhsi ahaaneed |

| Ytype tee wadajir | 6-6 | 2 | Shakhsi ahaaneed |

| Ku-habboon Suxulka Bir-La'aanta ah | 1/4-6 | 2 | Shakhsi ahaaneed |

| Ku-habboon Suxulka Bir-La'aanta ah | 1/8-6 | 1 | Shakhsi ahaaneed |

| xusul | M5-4 | 2 | Shakhsi ahaaneed |

| Waalka damin | M5-4 | 1 | Shakhsi ahaaneed |

| Waalka damin | M3-4 | 1 | Shakhsi ahaaneed |

| Cajalad ceeriin | 1 | Dulqaad | |

| Isgoysyada tee-ga ee nooca steelT-ka ah | 1 | Shakhsi ahaaneed | |

| Xidhiidhiyaha tooska ah | 1/8-6 | 1 | Shakhsi ahaaneed |

| SMEMAWire | 2 | xadhig | |

| cajalad koronto | 1 | duubid | |

| giraanta xiridda | φ16*2 | 2 | Shakhsi ahaaneed |

| giraanta xiridda | φ6*0.8 | 5 | Shakhsi ahaaneed |

| giraanta xiridda | φ7*1.8 | 5 | Shakhsi ahaaneed |

| giraanta xiridda | φ5*2 | 2 | Shakhsi ahaaneed |

| giraanta xiridda | φ55*3 | 2 | Shakhsi ahaaneed |